86-25-52251179

Yunjin Road Jianye District

Rm 1529-1531, Bldg 1

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

HGH35HA

HIWIN

HGH35HAZAC

HIWIN Linear Guide Rail HGH35HA Precision Linear Guide 35mm

High prcision HIWIN 35mm linear guide HGH35HA, the Linear guide rail max length is 4000mm each,if needs the lengths of more than 4000mm each pcs, we can provide the joint service, so will become the length according your request. HIWIN guide block HGH35HA are designed with load capacity and rigidity higher than other similar products with circular-arc groove and structure optimization. It features equal load ratings in the radial, reverse radial and lateral directions, and self-aligning to absorb installation-error, Thus, TaiWan HIWIN HG type linear guideways can achieve a long life with high speed, high accuracy and smotth linear motion.

HIWIN Linear Guide Rail HGH35HA Precision Linear Guide 35mm

High prcision HIWIN 35mm linear guide HGH35HA, the Linear guide rail max length is 4000mm each,if needs the lengths of more than 4000mm each pcs, we can provide the joint service, so will become the length according your request. HIWIN guide block HGH35HA are designed with load capacity and rigidity higher than other similar products with circular-arc groove and structure optimization. It features equal load ratings in the radial, reverse radial and lateral directions, and self-aligning to absorb installation-error, Thus, TaiWan HIWIN HG type linear guideways can achieve a long life with high speed, high accuracy and smotth linear motion.

| Item # | HGH35HA, HGH35HAZAC |

| Series | HG series |

| Block Type | Square type |

| Model Size | 35 mm |

| Load Type | Super heavy load |

| Block Mounting | Mounting from Top |

| Block | Standard type block |

Preload Class | Light Preload (0-0.02 C), Medium Preload (0.05-0.07 C) |

| Precision code | C |

| Dust Protection | Standard preotection (End seal and bottom seal) |

| Item # | HGH35HA, HGH35HAZAC |

| Series | HG series |

| Block Type | Square type |

| Model Size | 35 mm |

| Load Type | Super heavy load |

| Block Mounting | Mounting from Top |

| Block | Standard type block |

Preload Class | Light Preload (0-0.02 C), Medium Preload (0.05-0.07 C) |

| Precision code | C |

| Dust Protection | Standard preotection (End seal and bottom seal) |

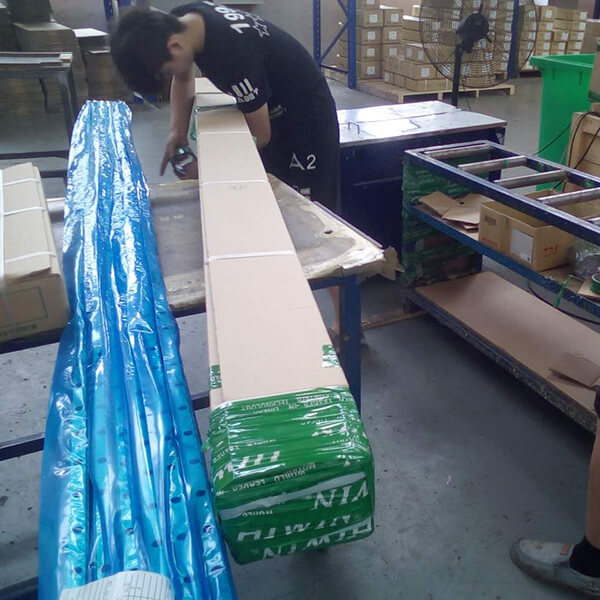

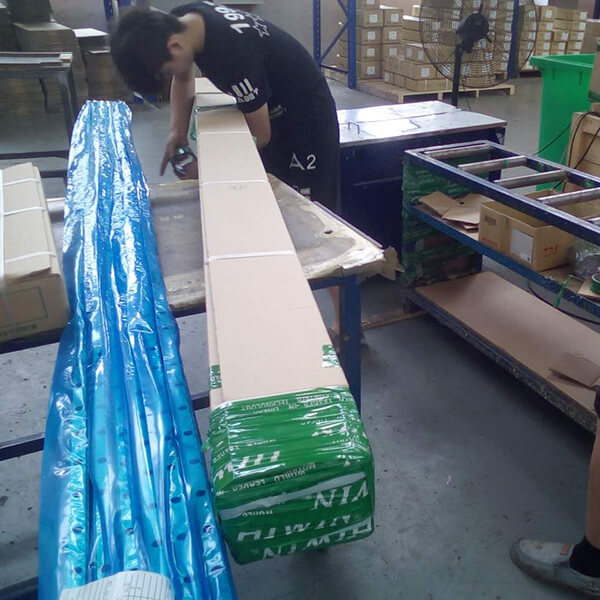

Single color box of original |  Suitable carton size |  Carton box for rail |

Remark: For the large quantity of the rail or linear carriage, We will package them with wooden box before shipment. |

Single color box of original |  Suitable carton size |  Carton box for rail |

Remark: For the large quantity of the rail or linear carriage, We will package them with wooden box before shipment. |

HIWIN guideways are supplied with a coating of anti-corrosion oil before being shipped. Please clean the oil before moving or running the blocks.

Recognition of master and subsidiary rails: For non-interchangeable type linear guideways, there are some differences between the master rail and subsidiary rail. The accuracy of the master rail’s datum plane is better than the subsidiary’s and it can be a reference side for installation. There is a mark “MA” printed on the rail. Check for the correct order before starting the installation. The rail number of master is an odd number and the rail number of subsidiary is an even number. Please install the rails according to the indication and carry on the installation according to the order for multi-rails installment (e. g.: 001 pairs 002 ; 003 pairs 004 etc.)

Recognition of datum plane: The datum plane (B) of rail is the side indicated by the arrow, which is marked on the top surface of the rail. The datum plane of block is smooth ground surface which shows as D in Figure 2.

Butt-joint rail: Butt-joint rail should be installed by following the arrow sign and ordinal number which is marked on the surface of each rail as shown in the figure 3. To avoid accuracy problems due to discrepancies between the 2 rails such as for matched pair, butt-joint rails, the jointed positions should be staggered as shown in figure 4.

Do not remove blocks from rails when assembling the guideways in machines as far as possible. Please use block inserts (please see Figure 5) if it is necessary to remove/ mount block from/ onto rail.

Please do not randomly mix block units and rails for non interchangeable type to avoid any installation problem.

To ensure the straightness of rail, please tighten the mounting bolts sequentially with a torque wrench to the specified torque. (Refer to HIWIN Technical Information).

HIWIN guideways are supplied with a coating of anti-corrosion oil before being shipped. Please clean the oil before moving or running the blocks.

Recognition of master and subsidiary rails: For non-interchangeable type linear guideways, there are some differences between the master rail and subsidiary rail. The accuracy of the master rail’s datum plane is better than the subsidiary’s and it can be a reference side for installation. There is a mark “MA” printed on the rail. Check for the correct order before starting the installation. The rail number of master is an odd number and the rail number of subsidiary is an even number. Please install the rails according to the indication and carry on the installation according to the order for multi-rails installment (e. g.: 001 pairs 002 ; 003 pairs 004 etc.)

Recognition of datum plane: The datum plane (B) of rail is the side indicated by the arrow, which is marked on the top surface of the rail. The datum plane of block is smooth ground surface which shows as D in Figure 2.

Butt-joint rail: Butt-joint rail should be installed by following the arrow sign and ordinal number which is marked on the surface of each rail as shown in the figure 3. To avoid accuracy problems due to discrepancies between the 2 rails such as for matched pair, butt-joint rails, the jointed positions should be staggered as shown in figure 4.

Do not remove blocks from rails when assembling the guideways in machines as far as possible. Please use block inserts (please see Figure 5) if it is necessary to remove/ mount block from/ onto rail.

Please do not randomly mix block units and rails for non interchangeable type to avoid any installation problem.

To ensure the straightness of rail, please tighten the mounting bolts sequentially with a torque wrench to the specified torque. (Refer to HIWIN Technical Information).

Have any Question ?

Call Us :

For Details